Engineering Services

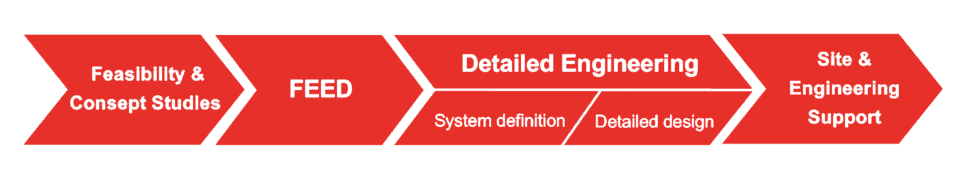

Nymo offers reliable and efficient engineering services, leveraging both in-house expertise and long-term partnerships to deliver value. From initial studies to detailed engineering, our services are provided within a proven ecosystem that ensures successful project execution.

Engineering as a Service

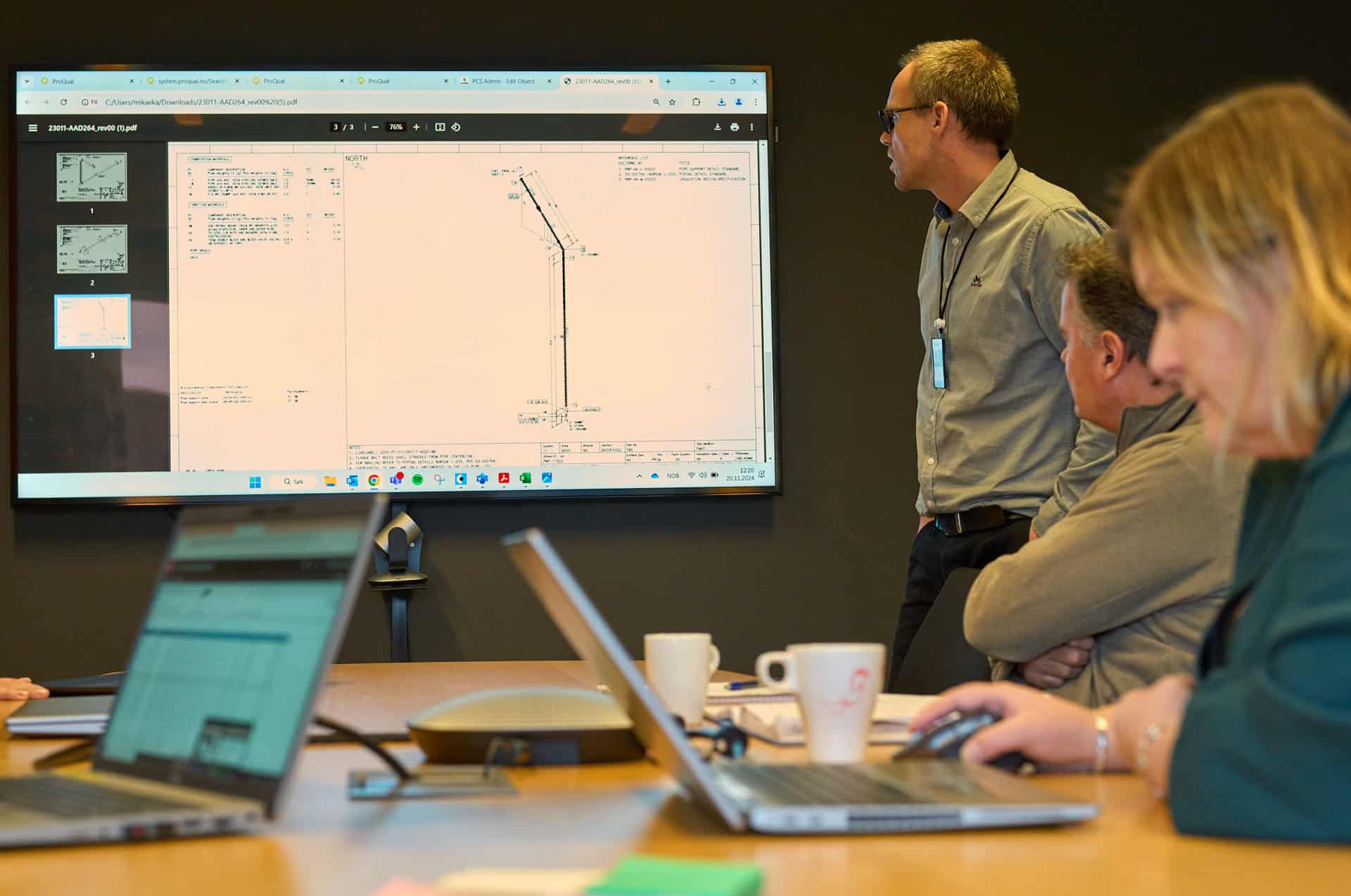

Nymo delivers proficient and efficient engineering services with a dedicated team of 60 skilled employees. Our teams proven track record, extensive networks and deep industry experience provide us with a comprehensive understanding of complex design and project execution.

Design and construction at the same location enable highly industrialized solutions.

We offer large to small teams, single or multi-discipline, from concept to detail design, executed inhouse or at clients premises as well as consultancy services.

Specialists in design

Nymo has a team of highly experienced engineers capable of conducting studies, concept engineering, and detailed engineering within oil and gas and other markets. Our expertise in designing topside and subsea modules, gas turbines accessories and advanced structures within oil & gas, provides a strong foundation for delivering solutions within a broad range of markets. With extensive experience as a total package supplier, we excel in creating fabrication-friendly detailed solutions.

Recent references

2017 - Johan Sverdrup - Design of drilling module

Nymo, together with Aibel, was awarded the contract on the Johan Sverdrup Drilling Platform (JSDP) by Equinor in the spring of 2015.

The contract was a total EPC contract, including responsibility for both design, procurement and fabrication. Nymo was given the overall responsibility for the drilling deck, the sub-structure and installation of the derrick (the Drilling Equipment Set, or DES), with a total weight of 3300 tons. Nymo received positive feedback both for good design solutions and top-quality execution of fabrication work. The work was carried out safely, without serious accidents, and the product was delivered complete and according to plan in September 2017.

Nymo and Aibel started design work together in February 2015. The structure was mainly fabricated by a subcontractor in Poland, while assembling and fitting was performed at Nymo’s own workshop in Vikkilen, Grimstad. Nymo completed the DES according to plan in September 2017. It was then loaded onto a barge and transported to the Klosterfjord, where it was handed over to Aibel. Here the DES was assembled with the rest of the drilling platform, which was completed and handed over to Equinor according to plan in spring 2018.

Nymo is proud to have been part of developing Johan Sverdrup and would like to thank Equinor and Aibel for the contract and good collaboration throughout the project!

2015 - North Dragon - Design of drilling module

Nymo signed a contract with Yantai CIMC Raffles Offshore in China for the design and construction of a drilling module for the North Dragon drilling rig.

The drilling module weighs approx. 2,300 tons and has a working volume of just over 300,000 hours. It will be mounted on a GM-4D Semi-sub. The drilling equipment for the rig is supplied by National Oilwell Varco (NOV).

The entire rig including the drilling deck will be classified by DNV.

2014 - Frigstad D90 - Design of drilling module

2011 - Island Innovator - Design of drilling module

Client: Maracc

Weight: 1600 tonnes

Contract awarded: 2007

Year of delivery: 2011

Maracc is currently developing the semi-submersible GM4000 drilling rig, named Island Innovator.

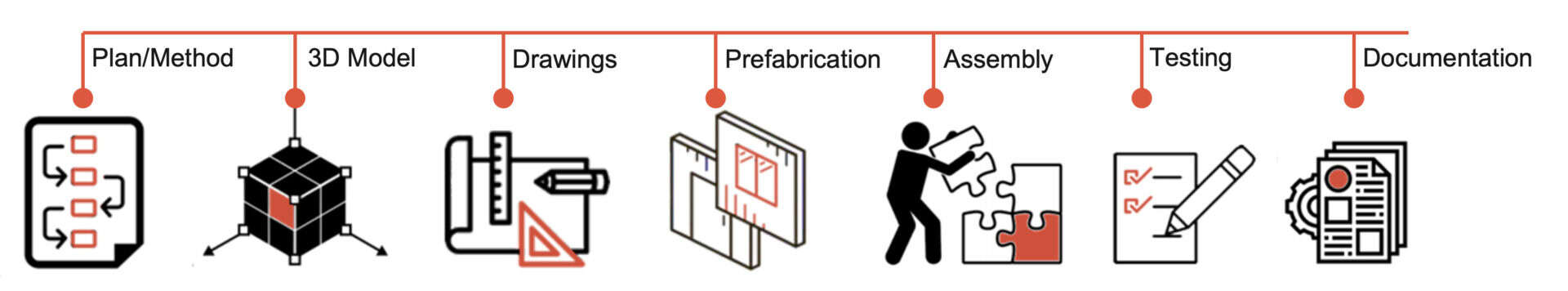

The GM4000 is a state of the art drilling module and setback tower from National Oilwell Varco and Nymo. The project is the latest of several successful projects for this partnership between two cornerstone companies from the southern region of Norway. NOV has been responsible for the concept layout, systems engineering and equipment supplies. Nymo performs the structural global analyses and structural design, detailed multidiscipline design engineering, detailed layout, fabrication engineering, construction, equipment installation, mechanical completion and LCI documentation.

Work at Nymo is progressing as planned at Nymo Grimstad Yard (Vikkilen) and shipment of the drilling module from Grimstad to China is set to April 2011.

Construction of the GM 4000 vessel and installation of the drilling rig is performed by COSCO Zhoushan Shipyard. The project is the first offshore project contracted at COSCO Zhoushan Shipyard.

Island Innovator will have a mud treatment module designed by NOV/Nymo and manufactured by Wison, in China.Design was delivered in 2008.

Hydraulics High Pressure Unit (HPU) for the “Island Innovator” has been constructed by Nymo.

Mobilization start-up is scheduled for end of May 2012 in Norway.

Digital collaboration hub

Digital collaboration

Nymo has made significant investments in digitalizing our agile project execution model to meet client and partner needs.

- Seamless integrations with partners and clients through our digital hub

- Advanced 3D multidiscipline modelling and visualization

- Fabrication progress reporting using 3D model visualization

- Intelligent engineering database

- Remote access for client to follow-up and verification

- Electronic “as-built” documentation as «digital twin» to operation